SMAC muaj cov khoom siv tiav rau cov kab tsuag pleev xim, cov kab txheej hmoov, cov kab electrophoresis, cov kab anodizing, kev kho ua ntej, kev ntxuav, kev ziab thiab kev kho, kev xa khoom, thiab kev kho cov pa roj thiab cov dej khib nyiab. Cov khoom lag luam SMAC siv dav hauv kev lag luam xws li tsheb, maus taus, cov khoom siv tsheb kauj vab, cov khoom siv IT, cov khoom 3C, cov khoom siv hauv tsev, rooj tog, cov khoom siv ua noj, cov khoom siv kho kom zoo nkauj, thiab cov tshuab tsim kho.

Tom qab cov khoom ua haujlwm tawm hauv qhov cub kho, nws nkag mus rau hauv lub kaw lus txias sai rau kev kho kom txias.

Kev txheej electrophoretic suav nrog kev siv lub zog hluav taws xob sab nraud los faib cov xim ionized uas dai rau hauv dej, uas ua rau lawv txheej rau saum npoo ntawm cov khoom ua haujlwm thiab tsim ib txheej tiv thaiv. Cov txheej txheem no muaj ntau qhov zoo:

Txheej Txheem Sib Npaug: Cov txheej txheem no tau siv sib npaug thoob plaws qhov chaw.

Kev nplaum zoo: Cov xim pleev xim lo rau ntawm qhov workpiece zoo.

Kev Poob Xim Tsawg Kawg Nkaus: Muaj kev pov tseg me ntsis ntawm cov khoom siv txheej, ua rau muaj kev siv ntau.

Cov Nqi Tsim Khoom Tsawg: Tus nqi tag nrho ntawm kev tsim khoom raug txo qis.

Kev Sib Xyaws Ua Los Ntawm Dej: Cov xim tuaj yeem sib xyaw nrog dej, tshem tawm cov teeb meem hluav taws thiab txhim kho kev nyab xeeb thaum lub sijhawm tsim khoom.

Cov yam ntxwv no ua rau electrophoretic txheej yog qhov kev xaiv nrov hauv ntau yam lag luam.

Lub tshuab ultrafiltration (UF) feem ntau muaj cov modules membrane, twj tso kua mis, kav dej, thiab cov cuab yeej siv, txhua yam sib sau ua ke. Txhawm rau kom ntseeg tau tias lub tshuab ultrafiltration ua haujlwm li qub, nws feem ntau muaj cov tshuab lim dej thiab ntxuav. Lub hom phiaj tseem ceeb yog kom ntev lub neej kev pabcuam ntawm cov xim pleev xim, txhim kho qhov zoo ntawm cov txheej txheem, thiab xyuas kom meej tias muaj cov ultrafiltrate xav tau rau kev ua haujlwm li qub ntawm cov khoom siv.

Lub tshuab ultrafiltration yog tsim los ua lub tshuab ncig ncaj qha: cov xim electrophoretic raug xa mus los ntawm lub twj tso kua mis mus rau lub lim ua ntej ntawm lub tshuab ultrafiltration rau 25 μs ntawm kev kho ua ntej. Tom qab qhov no, cov xim nkag mus rau hauv lub tshuab tseem ceeb ntawm lub tshuab ultrafiltration, qhov twg cov kua sib cais tshwm sim los ntawm lub module membrane. Cov xim concentrated sib cais los ntawm lub tshuab ultrafiltration raug xa rov qab mus rau lub tank electrophoretic los ntawm cov kav dej xim concentrated, thaum lub ultrafiltrate raug khaws cia rau hauv lub tank cia ultrafiltrate. Lub ultrafiltrate hauv lub tank cia tom qab ntawd raug xa mus rau qhov chaw siv los ntawm lub twj tso kua mis hloov.

Lub Hnab Ua Kub - Ci thiab Kho

Lub hnab cua sov siv rau hauv cov txheej txheem ci thiab kho cov xim pleev, tshwj xeeb tshaj yog hauv kev lag luam xws li tsheb thiab kev tsim khoom. Nov yog kev piav qhia luv luv:

1. Kev Ua Haujlwm: Lub hnab cua sov muab cua sov tswj tau rau cov khoom ua haujlwm uas tau pleev xim, ua kom cov xim lossis lwm yam txheej pleev xim qhuav. Qhov no ua kom ntseeg tau tias cov txheej pleev xim lo rau zoo thiab ua tiav qhov tawv thiab kav ntev raws li xav tau.

2. Tsim: Cov hnab cua sov feem ntau yog ua los ntawm cov ntaub ntawv uas tiv taus cua sov thiab tsim los kom faib cua sov thoob plaws qhov chaw ntawm cov khoom ua haujlwm.

3. Kev Tswj Kub: Lawv feem ntau tuaj nrog cov txheej txheem tswj kub uas ua rau hauv kom tswj tau qhov kub uas xav tau, kom ntseeg tau tias cov txiaj ntsig zoo ib yam.

4. Kev Siv Tau Zoo: Siv lub hnab cua sov tuaj yeem txo qhov kev siv hluav taws xob piv rau cov qhov cub ib txwm muaj, vim nws tuaj yeem tsom cua sov ncaj qha rau ntawm cov khoom uas tab tom kho.

5. Daim Ntawv Thov: Feem ntau siv rau hauv cov txheej txheem txheej hmoov, pleev xim electrophoretic, thiab lwm yam kev siv uas xav tau kev ua tiav ruaj khov.

Txoj kev no ua kom zoo dua qhov zoo ntawm cov khoom tiav thaum ua kom siv cov peev txheej tau zoo.

Kev Thauj Khoom

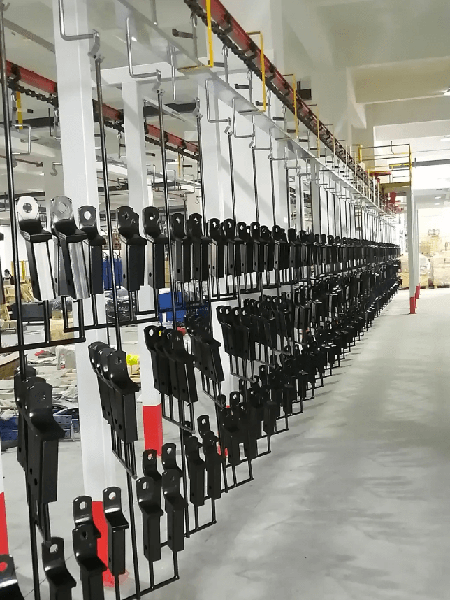

Lub tshuab nqa khoom saum toj kawg nkaus muaj ntau yam tseem ceeb, suav nrog lub tshuab tsav, lub cuab yeej rub nrog cov hnyav, cov saw hlau, cov kab ncaj, cov kab nkhaus, cov kab telescopic, cov kab tshuaj xyuas, cov tshuab lubrication, cov kev txhawb nqa, cov khoom dai khoom thauj, cov tshuab tswj hluav taws xob, thiab cov khoom siv tiv thaiv kev thauj khoom ntau dhau. Nws cov haujlwm tseem ceeb yog raws li nram no:

1. Kev Ua Haujlwm: Thaum lub cev muaj zog tig, nws tsav cov txoj kab los ntawm lub tshuab txo qis, uas ua rau lub zog tag nrho cov saw hlau hla kev. Cov khoom ua haujlwm raug dai ntawm lub tshuab thauj khoom siv ntau hom kev dai, ua rau yooj yim tuav thiab ua haujlwm.

2. Kev Kho Kom Haum: Qhov layout ntawm txoj kab conveyor yog txiav txim siab los ntawm qhov chaw ua haujlwm tshwj xeeb thiab cov txheej txheem khoom, ua tau raws li cov kev xav tau ntawm kev tsim khoom.

3. Kev Ua Haujlwm ntawm Cov Saw: Cov saw ua haujlwm ua lub zog rub ntawm lub tshuab xa khoom. Lub tshuab ua kom lubrication tsis siv neeg tau teeb tsa rau ntawm cov saw kom ntseeg tau tias txhua qhov sib txuas uas txav tau txais cov roj nplua nyeem kom raug.

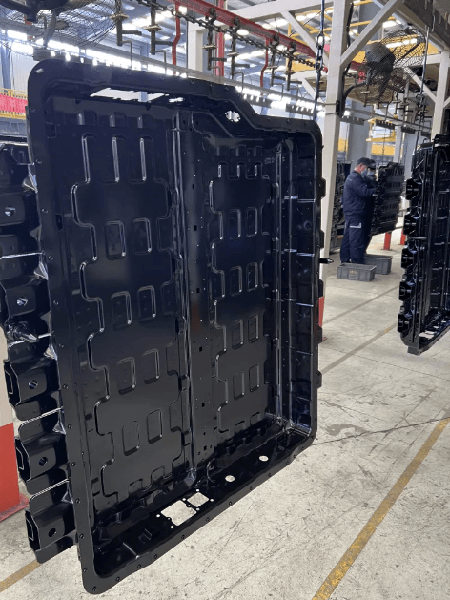

4. Cov Khoom Dai: Cov khoom dai txhawb nqa cov saw hlau thiab dais lub nra ntawm cov khoom uas raug thauj mus los ntawm txoj kev. Lawv txoj kev tsim qauv yog txiav txim siab los ntawm cov duab ntawm cov khoom ua haujlwm thiab cov txheej txheem tshwj xeeb. Cov hooks ntawm cov khoom dai tau dhau los ntawm kev kho cua sov kom ntseeg tau tias lawv tiv taus kev siv ntev yam tsis muaj kev tawg lossis deforming.

Lub tshuab xa khoom no ua rau kev ua haujlwm zoo dua thiab kev ntseeg tau hauv ntau yam kev siv hauv kev lag luam.

Lub sijhawm tshaj tawm: Lub Xya Hli-25-2025