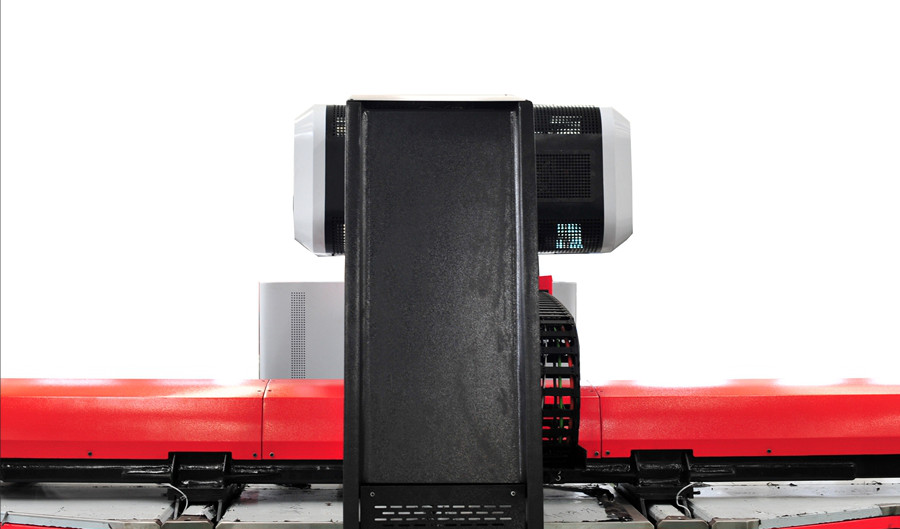

High Quality CNC Turret Punch Tshuab

1. Ib leeg servo lub cev muaj zog tsav, txais lub zog loj ncaj qha tsav servo lub cev muaj zog thiab tsav tsheb nrog lub peev xwm ntau dhau kom paub txog kev siv hluav taws xob tsawg, kev sib kis tau zoo, kev ua tau zoo thiab kev saib xyuas yooj yim.

(1) Adjustable ceev thiab mob stroke

ib. Lub punch stroke tuaj yeem xaiv raws li qhov tuab ntawm daim ntawv txiav, txhim kho kev ua haujlwm zoo.

b. Lub punch ceev yog adjustable thaum lub sij hawm txhua qhov chaw ntawm txhua qhov chaw nres tsheb,

c. Lub tshuab tuaj yeem paub qhov kev kub ceev nrawm thaum lub sijhawm khiav thiab qis qis thaum lub sijhawm punch tiag, nyob rau hauv txoj kev no, cov punch zoo tuaj yeem txhim kho tau zoo, thiab tsis muaj suab nrov thaum lub punch.

(2). Lub kaw lus nta nrog kev tiv thaiv dhau tam sim no thiab cov khoom siv tiv thaiv kev tiv thaiv overload.

(3). Lub punch quab yuam tuaj yeem hloov kho raws li daim ntawv tuab thiab ram khiav ceev kom ua rau cov punching zoo mus txog qib siab.

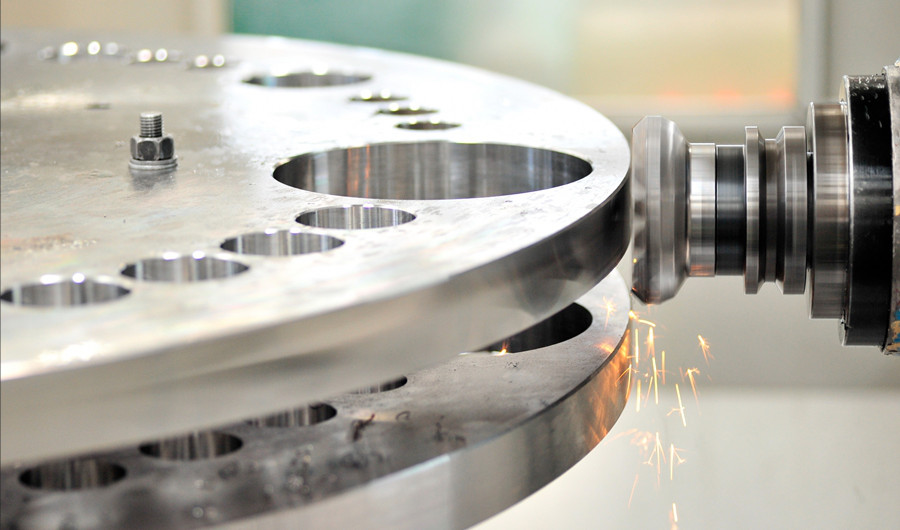

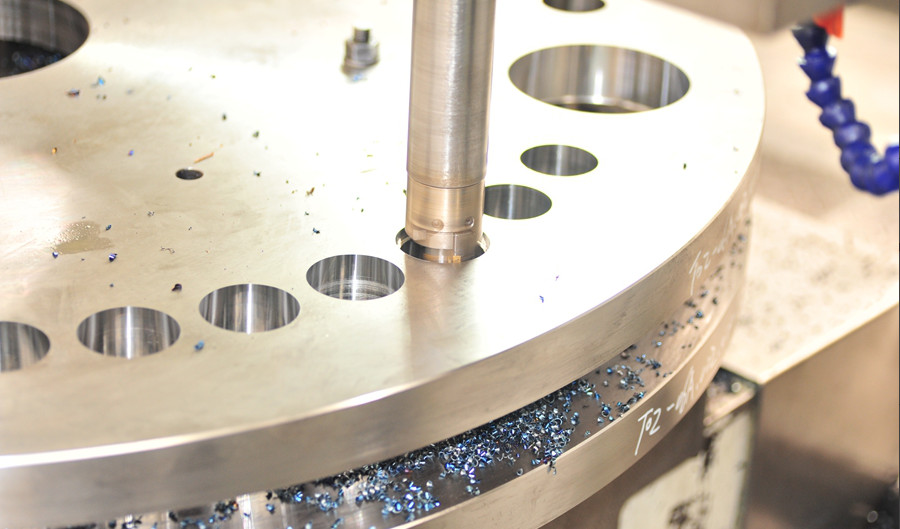

2. Lub turret nrog bushing yog txheej txheem ua khub

Lub turret yog ua tiav los ntawm cov cuab yeej tshwj xeeb los xyuas kom meej lub coaxiality ntawm lub sab sauv thiab sab turret thiab nthuav cov kev pab cuam lub neej ntawm tooling; lub bushed turret simplifies lub turret qauv kom ntev lub neej kev pab cuam; Cov cuab yeej siv ntev tuaj yeem siv los ua kom cov kev taw qhia raug thiab nthuav cov cuab yeej siv lub neej (rau cov ntawv tuab).

3. Imported pneumatic, lubricating thiab hluav taws xob Cheebtsam kom ntseeg tau tias tag nrho lub tshuab.

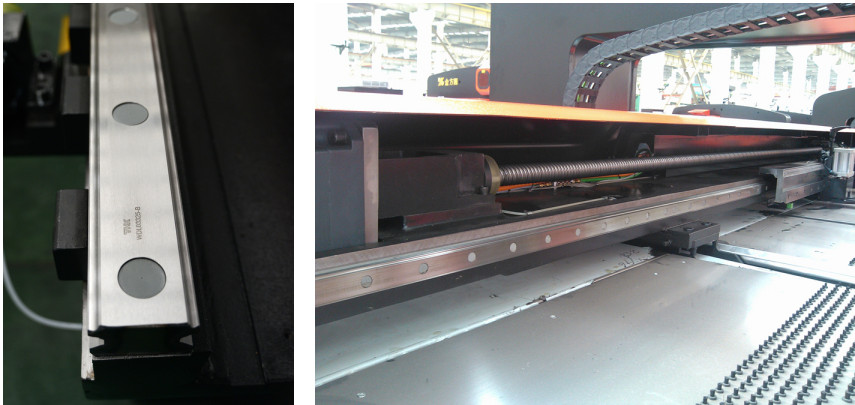

4. Cov lus qhia loj loj thiab cov pob ntsia hlau los ntawm Nyiv lossis Lub Tebchaws Yelemees ua kom muaj kev noj qab haus huv zoo.

5. Cov txhuam tawv tawv thiab pob sib xyaw ua haujlwm ua haujlwm txo cov suab nrov thiab kev co thaum khiav thiab tseem tiv thaiv daim ntawv nto.

6. O-hom welded ncej tau vibrated rau ob zaug, qhov kev ntxhov siab tau raug tshem tawm tag nrho. Lub thav duab yog ua tiav los ntawm lub teb chaws Yelemees SHW dual-sab pentahedron ua chaw nyob rau hauv ib lub sij hawm, tsis tas yuav ua rau lub sij hawm thib ob positioning.

7. Floating clamp nrog loj clamping quab yuam kom ruaj khov noj; integrated carriage kom zoo rigidity thiab yooj yim txav ntawm clamp.

8. Lub kaw lus muaj qhov tshwj xeeb nrog kev ua haujlwm ntawm kev tiv thaiv tsis siv neeg clamp kom tsis txhob muaj kev puas tsuaj ntawm cov cuab yeej thiab clamp, kom ntseeg tau qhov kev khiav haujlwm tas li.

9. Nws pib-index adopts siab raug cab log thiab cab mechanism, kom ntseeg tau siab indexing. Qhov Max. tooling txoj kab uas hla tuaj yeem ncav cuag 88.9mm thiab nws pib-index tuaj yeem nthuav mus rau 4 nos.

10. Integrated beam qauv ua kom lub carriage thiab beam mus rau hauv ib feem, ua kom lub rigidity thiab coj qhov tseeb positioning. Lub tshuab tuaj yeem khiav ntau ruaj khov thaum lub sij hawm pub mis ceev thiab nws tso qhov kawg rau qhov deflection ntawm X thiab Y axes.

11. X axis: txais servo lub cev muaj zog los tsav cov neeg ua haujlwm siab pob thiab lub tsheb thauj khoom yog tshwj xeeb nrog kev nruj nruj thiab tsim qauv. Y axis: servo lub cev muaj zog ncaj qha tsav cov khoom noj khoom haus uas txuas nrog lub tshuab kev taw qhia, cais hom nqaj yog tsau nrog cov khoom noj khoom noj, thiab lub zog ua haujlwm yuav raug xa mus rau lub tshuab thav duab & hauv av los ntawm kev pub noj khib thiab kev taw qhia kom txo tau tus kheej kev co ntawm cov nqaj. Cov qauv no yog featured nrog cov yam ntxwv ntawm zoo rigidity, lub teeb nyob rau hauv qhov hnyav, tsis tshua muaj lub ntiajteb txawj nqus, thiab zoo dynamic teb nyob rau hauv tag nrho cov pub system, ruaj khov khiav thiab zoo meej.

12. Central lubrication system yog saws los xa cov roj lubrication mus rau cov txheeb ze lubricating taw tes ncaj qha, txo cov kev sib txhuam ntawm txhua tus khub ua haujlwm thiab ua kom lub neej ua haujlwm.

13. Anti-daim ntawv-deformation hloov thiab daim ntawv-tiv thaiv stripping hloov tau txais yuav.

| Tsis muaj. | Lub npe | Qty. | Lus ceeb toom |

| 1 | Daim ntawv teev npe | 1set ib | |

| 2 | Daim ntawv pov thawj zoo | 1set ib | |

| 3 | Mechanic Operation Manual | 1set ib | |

| 4 | Kev Siv Hluav Taws Xob Ua Haujlwm | 1set ib | |

| 5 | Kev kos duab Foundation | 1set ib | |

| 6 | Hluav taws xob tus thawj xib fwb Drawing | 1set ib | |

| 7 | Auto-program Software System Documents | 1set ib | |

| 8 | DBN Electrical Principal Drawing | 1set ib | |

| 9 | Tooling phau ntawv | 1set ib | |

| 10 | CNC system manual | 1set ib | |

| 11 | Tooling Drawing | 1set ib |

| Tsis muaj. | Lub npe | Ntsuas | Qty. |

| 1 | Dual-head Spanner | 5.5 × 7-22 × 24 | 1set ib |

| 2 | Moveable Spanner | 200 | 1 nr. |

| 3 | Socket Head Spanner | S1.5-S10 | 1set ib |

| 4 | Hla Screwdriver | 100 × 6 | 1 nr. |

| 5 | Roj Phom | HS87-4 Q | 1 nr. |

| 6 | Roj Roj Lubrication Pump Compressor Phom | SJD-50Z | 1 nr. |

| 7 | rab phom siab | 1set ib | |

| 8 | T shape pob qhov rooj | M14 × 1.5 | 1 nr. |

| 9 | Txoj kev hloov | M12 PNP SN = 2 open | 1set ib |

| 10 | Txoj kev hloov | M12 PNP SN=2 close | 1 nr. |

| 11 | Spanner | T09-02,500,000-38 | 1 nr. |

| 12 | Spanner rau roj lub tog raj kheej hloov | 1set ib | |

| 13 | Cov kav dej mos | Ø 12 | 1 nr. |

| 14 | Soft pipe pin | KQ2H12-03AS | 1set ib |

| 15 | Foundation qhov chaw | 1 nr. |

| Tsis muaj. | Lub npe | Ntsuas | Qty. | Lus ceeb toom |

| 1 | Clamp iav board | 3 nos. | T02-20A.000.000-10C T02-20A.000.000-24A | |

| Clamp portective board | 6 nos. | T02-20A.000.000-09C Los yog T02-20A.000.000-23A | ||

| 2 | Caij nplooj ntoos hlav me me ntsia hlau hauv clamp | M4x 10 | 20 nrv. | T02-06,001,000-02 |

| M5x12 | ||||

| 3 | ntsia hlau hauv clamp Inner ntsia hlau | M8x 1 x 20 | 20 nr. | |

| 4 | Shearing hniav | 30 T | 2 nos. | T09-16.310,000-0.1.2 |

| 5 | Sab hauv ntsia hlau | M8x 1 x 20 | 4 nos. |

FANUC CNC system yog qhov tshwj xeeb CNC system tsim los ntawm Nyiv FANUC tshwj xeeb tshaj yog rau lub hom phiaj kom tau raws li cov yam ntxwv ntawm lub tshuab no, txhim kho kev ntseeg siab ntawm lub tshuab mus rau qhov loj.

I, System Yam ntxwv

1. Daim duab thiab punch muaj nuj nqi;

2. Yooj yim universal G code program rau kev ua haujlwm yooj yim;

3. Universal RS232 tus qauv chaw nres nkoj sib txuas lus nrog lub computer yooj yim;

4. Advanced tag nrho cov servo lub cev muaj zog thiab servo system;

5.10.4 "LCD muaj yeeb yuj zaub;

6. Pulse encoder semi-loop tawm tswv yim;

7. EMS nco: 256K;

8. Kev pab cuam teb, chaw ua haujlwm;

9. Suav thiab Askiv zaub;

10. Muaj nuj nqi ntawm daim duab simulation;

11.Ib lub peev xwm loj PCMCIA daim npav rau kev thaub qab ntawm qhov system parameter, ntaiv kos duab thiab kev ua haujlwm, thiab paub txog cov txheej txheem hauv online ntawm kev ua haujlwm loj;

12. Kev nce hauv qhov tsawg tshaj plaws, txoj haujlwm nrhiav kom tau ad servo tswj kom paub txog kev kub ceev thiab kev ua haujlwm siab;

13. Lub lag luam khawm ntawm lub vaj huam sib luag tuaj yeem txhais tau raws li qhov yuav tsum tau ua tiag tiag;

14. Super siab ceev clutch cov ntaub ntawv cables nrog me ntsis cable txuas;

15. Kev sib koom ua ke siab, tshwj xeeb software. Lub sijhawm luv luv rau kev pib, cov ntaub ntawv yuav tsis ploj yog tias lub zog tsis txaus ntawm cov khoom tam sim ntawd;

16. Cia ntawm 400 daim ntawm qhov kev pab cuam.

1. Linear axes: X, Y axes, rotating axes: T, C axes, punch axis: Z axis;

2. Tswb rau hluav taws xob yuam kev xws li over-stroke.

3. Muaj nuj nqi ntawm kev kuaj tus kheej.

4. Muaj nuj nqi ntawm kev txwv mos.

5. Universal G code rau kev pab cuam;

6. Kev ua haujlwm ntawm cov cuab yeej them nyiaj;

7. Muaj nuj nqi ntawm cov ntsia hlau nrug them nyiaj;

8. Muaj nuj nqi ntawm qhov rov qab qhov sib txawv them nyiaj;

9. Kev ua haujlwm ntawm kev sib koom tes deflection;

10. Muaj nuj nqi ntawm reposition;

11. Muaj nuj nqi ntawm AUTO, MANUAL, JOG hom;

12. Muaj nuj nqi ntawm kev tiv thaiv clamp;

13. Kev ua haujlwm ntawm lub xauv ntawm sab hauv sau npe;

14. Kev ua haujlwm ntawm kev ua haujlwm parameter;

15. Kev ua haujlwm ntawm sub-program;

16. Kev ua haujlwm nrawm nrawm thiab xuas nrig ntaus;

18. Kev ua haujlwm ntawm M code;

19. Qhov kev pab cuam meej thiab nce ntxiv;

20. Cua txias, unconditioning dhia.

Programing software qhia

Peb txais CNCKAD los ntawm METALIX Company. Lub software yog ib txheej ntawm CAD / CAM tsis siv neeg programming software los ntawm kev tsim mus rau ntau lawm. Nrog rau kev tswj cov tsev qiv ntawv pwm, kev xaiv hom tsis siv neeg, kev ua kom zoo ntawm txoj kev thiab lwm yam haujlwm, tuaj yeem ua tiav los ntawm CAD daim duab NC cov txheej txheem ua haujlwm. Koj tuaj yeem ua tiav ib qhov programming, tsis siv neeg zes thiab ua tiav pob.

Kev ua haujlwm ntawm DrawingCNCKAD cov duab muaj zog, yooj yim thiab siv tau, ntxiv rau cov qauv kos duab ua haujlwm raws li cov yam ntxwv ntawm cov ntawv hlau, ntxiv qee qhov kev kos tshwj xeeb xws li kev txiav, puag ncig, daim duab peb sab, lub kaum sab xis thiab cov duab contour, kneading, kos kho thiab kho tsis siv neeg, txiav lossis stamping, Suav cim DXF / IGES / CADL / DWG cov ntaub ntawv tawm tswv yim thiab lwm yam.

b) Muaj nuj nqi ntawm Punching

Featured nrog tsis siv neeg xuas nrig ntaus, pwm tshwj xeeb, tsis siv neeg indexing, tsis siv neeg txav chaw, ntug txiav, thiab lwm yam haujlwm.

c) Kev ua haujlwm ntawm shearing

Tsis siv neeg contour xyuas thiab kho qhov tsis zoo ntawm cov khoom siv, thickness, ib qho kev txiav, txiav, thiab shear hloov chaw, thiab lwm yam haujlwm, kev siv phaj tsis siv neeg shear processing.

d) Post processing

Kev ua haujlwm tsis siv neeg lossis kev sib tham sib npog tag nrho cov txheej txheem: stamping, laser, plasma, hluav taws kub, dej txiav thiab milling.

Advanced post processing tuaj yeem tsim txhua yam kev ua tau zoo NC code, kev txhawb nqa subroutine, macro program, xws li kev ua kom zoo ntawm cov cuab yeej txoj kev thiab qhov tsawg tshaj plaws pwm rotation, txhawb kev txhaj tshuaj, lub tshuab nqus tsev nqus cov haujlwm xws li cov khoom siv thiab zawv zawg thaiv tus nqi.

Hloov cov kev pab cuam mus rau lwm lub tshuab tsuas yog xav tau ob peb clicks los ntawm tus nas.Cov no yog muab los ntawm CNCKAD tom qab kev ua haujlwm, los ntawm kev tshem tawm cov ntaub ntawv hauv computer ntau dhau uas ua rau kev ua haujlwm zoo dua.

e) CNC Graphical simulation

Software txhawb nqa txhua daim duab simulation ntawm CNC program, suav nrog kev sau ntawv ntawm CNC code, kev kho cov txheej txheem kuj yooj yim heev, cov software tuaj yeem kuaj xyuas qhov tsis raug, xws li qhov poob tsis raug clamp thiab qhov kev ncua deb, thiab lwm yam.

f) Kev hloov pauv ntawm NC rau Drawing

Ob txhais tes sau lossis lwm yam NC code, tuaj yeem hloov pauv mus rau hauv cov duab kos duab.

g) Daim ntawv qhia hnub

Muaj peev xwm luam tawm cov ntaub ntawv qhia, suav nrog tag nrho cov ntaub ntawv xws li cov naj npawb ntawm cov khoom, ua cov ntaub ntawv xws li lub sijhawm, pwm teeb thiab lwm yam.

h) DNC kis tau tus mob

Txais Windows interface ntawm cov kis tau tus mob module, kom kev sib kis ntawm PC thiab cov cuab yeej siv tshuab tau yooj yim heev.

1) Txhawb nqa tag nrho cov qauv tam sim no ntawm CNC turret punch, laser txiav tshuab, ntshav txiav tshuab thiab nplaim taws txiav tshuab thiab lwm yam cuab yeej tshuab.

2) Txhawb nqa tag nrho cov txheej txheem ntawm CNC cov cuab yeej ua haujlwm, suav nrog kev kos duab, tsis siv neeg lossis kev sib tham ua haujlwm, kev ua haujlwm tom qab, CNC simulation program, phau ntawv thiab txiav tsis siv neeg, NC cov ntaub ntawv rub tawm thiab upload thiab lwm yam.

3) 、 Muaj peev xwm nkag ncaj qha Autocad, SolidEdge, SolidWork thiab CadKey thiab lwm yam suav nrog tag nrho cov npe nrov CAD software tsim cov duab duab.

4) 、 Cov software txhawb nqa ntau yam khoom siv sib txawv ntawm cov lej sib txawv, tuaj yeem tso NC qhov chaw tsim cov khoom siv sib txawv, rau ntau yam khoom siv tib lub sijhawm thaum ua haujlwm.

Tsis Siv Neeg Repositioning

Thaum lub phaj loj loj dua li qhov ntau yam, lub tshuab cia li rov tso dua, thiab tom qab ntawd mam li tsim cov lus qhia muab tso rau; yog tias tus neeg siv muaj cov kev cai tshwj xeeb, tuaj yeem hloov kho lossis tshem tawm ntawm lawv tus kheej re positioning cov lus qhia.

Tsis siv neeg clamp zam

Cov lus qhia tsim los ntawm kev tso chaw cia uas tuaj yeem ua rau lub clamp tsis txhob tuag, txo cov khib nyiab; Txawm hais tias lub phaj yog ib feem lossis ob peb qhov ntawm lub phaj steel, tuaj yeem paub txog kev ua haujlwm ntawm kev zam.

Sawb cov khoom ua tiav

Txhawm rau txo qhov deformation ntawm cov khoom hauv cov txheej txheem stamping, cov txheej txheem ua cov khoom siv sawb tuaj yeem siv tau, thiab cov cuab yeej txiav tuaj yeem siv rau pem hauv ntej lossis sab nraub qaum ntawm ceg qhia.

Cov txheej txheem pruning

Ua ke nrog kev ua haujlwm ntawm cov ntug xuas nrig ntaus, tsis siv neeg xuas nrig ntaus uas muaj peev xwm xuas nrig ntaus cov khoom tawg nyob ib ncig ntawm ntug.

Ib leeg calmp txav tau

Nrog lub tshuab txav clamp tuaj yeem tsim los ntawm software txiav txav clamp los ntawm NC cov lus qhia.

Minimun tuag rotation

Qhov tsawg kawg tuag kev xaiv tuaj yeem txo qhov hnav ntawm qhov chaw nres tsheb indexing tsis siv neeg thiab txhim kho kev tsim khoom.

Muaj nuj nqi ntawm ntau yam Punching

Muaj nuj nqi ntawm daim duab peb sab xuas nrig ntaus, bevel xuas nrig ntaus, arc xuas nrig ntaus thiab lwm yam tshwj xeeb thiab zoo xuas nrig ntaus txoj kev.

Muaj nuj nqi ntawm Strong Auto-Punching

Tsis Siv Neeg Punching nta muaj xws li tsis siv neeg micro kev sib txuas, kev xaiv ntse ntawm cov pwm thiab muaj txiaj ntsig ntawm kev tshawb pom lub tswb thiab lwm yam haujlwm.

I) Tsis siv neeg txiav kev ua haujlwm

METALIX CNCKAD muaj AutoNest tivthaiv uas yog ib txheej ntawm cov phaj tiag tiag tsis siv neeg optimization nesting software, uas tuaj yeem paub tag nrho cov ntawv hlau optimization ntawm cov txheej txheem kev.

1. Huab cua: ntsuas kev ua haujlwm siab yuav tsum ntau dua 0.6mPa, huab cua ntws: ntau dua 0.3m3 / min

2. Fais fab tuag: 380V, 50HZ, lub zog hloov pauv: ± 5%, lub zog hluav taws xob ntawm 30T yog 45KVA, lub zog hluav taws xob muaj zog yog 25mm², qhov hluav taws xob yog 100A. Yog tias cov khoom siv hluav taws xob tsis ruaj khov, qhov stabilizer xav tau, yog tias muaj hluav taws xob xau, yuav tsum muaj kev tiv thaiv.

3.Hydraulic roj: (SHELL) Tonna T220, Los yog lwm yam roj rau kev taw qhia thiab rail lubrication.

Cov roj lubrication: 00 #-0 # Cov roj siab siab (GB7323-94), cov lus qhia: hauv qab 20 ° C siv 00 # Cov roj siab siab, siab tshaj 21 ° C siv 0 # Cov roj siab siab heev

| Hom | Lub npe | Lus hais | Kub |

| Plhaub | EPO | 0 # Cov roj siab siab heev | 21 ° C saum toj no |

| Plhaub | GL00 ua | 00# Cov roj siab heev | 20 ° C hauv qab no |

3. Ib puag ncig kub: 0 ° C - + 40 ° C

4. Ib puag ncig cov av noo: txheeb ze av noo 20-80% RH (un-condensation)

5. Khaws kom deb ntawm qhov muaj zog vibration lossis cuam tshuam ntawm electromagnetism

6. Ib puag ncig nrog cov plua plav me me, tsis muaj pa phem

7. Npaj lub hauv paus raws li lub hauv paus kos duab

8. Tus neeg siv yuav tsum xaiv tus kws tshaj lij lossis tus kws tshaj lij rau kev cob qhia, kev kawm keeb kwm ntawm leej twg yuav tsum yog tsawg kawg yog kawm tiav hauv tsev kawm qib siab technical, thiab npaj rau lub sijhawm ntev.

11.Yuav tsum npaj lub hauv paus raws li daim duab kos

12. Ib qho qhib 65mm spanner ciaj ntswj, ib qho kev txhawb nqa pas nrig tom qab qhov cub, los kho lub hauv paus theem.

13. Ntau tshaj 5 litres ntawm cov roj av huv si, ntau cov ntaub pua plag, ib rab phom, cov roj lubricating, li 1 litres rau cov cuab yeej siv tshuab thiab pwm.

14 nrog ib tug Ф10 * 300 thiab ib tug Ф16 * 300 tooj liab rods rau pwm installation. Ntev beam (fuselage thiab beam yog ntim nyias, tab sis kuj los npaj cov khoom xa tuaj)

15 lub dial qhia (0-10mm ntau), siv los debug X thiab Y axis perpendicularity.

16 thaum cov cuab yeej ncav cuag lub Hoobkas, npaj 20T tsheb los yog crane rau nqa khoom

17.Yog V axis nruab nrog dej chiller lub cev muaj zog, ntsig txog qhov nruab nrab cua txias yuav tsum tau npaj, qhov ntim yog 38L

Lwm yam teeb meem uas tsis tau them yuav tsum muaj kev txhais lus thiab kev sib koom tes ntxiv

CNC Turret Punch Tshuab; turret punch; turret punch xovxwm; cnc xuas nrig ntaus; turret punching tshuab; cnc punch xovxwm; cnc turret punch xovxwm; cnc turret punch; cnc punch tshuab; turret punch rau muag; turret punch xovxwm tshuab; cnc punch xovxwm tshuab turret xuas nrig ntaus tshuab; cnc xuas nrig ntaus tshuab thiab dabtsi yog khoov tshuab; Tus lej tswj turret punch xovxwm; servo tsav turret punch xovxwm; turret punch xovxwm muag

| Tsis muaj. | Specification | Chav tsev | Tshuab Qauv | ||

| MT 300 E | |||||

| 1 | Max. Punch Force | kN | 300 | ||

| 2 | Hom Tsav Tsheb Loj | / | Ib-lub cev muaj zog tsav | ||

| 3 | CNC System | / | FANUC CNC system | ||

| 4 | Max. Daim Ntawv Txheej Txheem Loj | mm | 1250 * 5000 (nrog ib reposition) | 1500 * 5000 (nrog ib reposition) | |

| 5 | No. ntawm Clamp | tsis muaj. | 3 | ||

| 6 | Max. Txheej Txheej Thickness | mm | 3.2/6.35 Nws | ||

| 7 | Max. Punch Diameter ib zaug | mm | ib 88.9 | ||

| 8 | Main Strike Stroke | mm | 32 | ||

| 9 | Max. Punch Ntaus ntawm 1mm Pace | hpm ib | 780 ua | ||

| 10 | Max. Punch Kub ntawm 25mm Pace | hpm ib | 400 | ||

| 11 | Max. Nibbling Ceev | hpm ib | 1800 | ||

| 12 | No. ntawm Repositioning Lub tog raj kheej | teeb | 2 | ||

| 13 | Tsis muaj chaw nres tsheb | tsis muaj. | 32 | ||

| 14 | No. AI | tsis muaj. | 2 | ||

| 15 | No. ntawm Tswj Axis | tsis muaj. | 5 (X, Y, V, T, C) | ||

| 16 | Tooling Hom | / | Hom ntev | ||

| 17 | Hom rooj ua haujlwm | / | Hauv qab 3.2mm: Txhuam txhuam ruaj worktable (Nqa cov khoom thauj khoom tuaj yeem ntxiv raws li kev xaiv) | ||

| 3.2 hli: Tag nrho cov khoom ua haujlwm | |||||

| 18 | Max. Pub ceev | X axis | m/min | 80 | |

| Y Axis | 60 | ||||

| XY ua ke | 100 | ||||

| 19 | Turret Ceev | rpm ua | 30 | ||

| 20 | Tooling Rotation ceev | rpm ua | 60 | ||

| 21 | Qhov tseeb | mm | ± 0.1 | ||

| 22 | Max. Load Capacity | Kg | 100/150 rau pob worktable | ||

| 23 | Main Lub cev muaj zog | kVA ua | 45 | ||

| 24 | Tooling hom | / | ywj siab ceev disassembly hom | ||

| 25 | Cua Siab | MPa | 0.55 ib | ||

| 26 | Kev siv cua | L / min | 250 | ||

| 27 | CNC nco Capacity | / | 512k ua | ||

| 28 | Clamp dead zone nrhiav kom tau | / | Y | ||

| 29 | Sheet-anti-stripping Hloov | / | Y | ||

| 30 | Anti-Sheet-Deformation Hloov | / | Y | ||

| 31 | Daim duab Dimension | mm | 5350 × 5200 × 2360 hli | 5850 × 5200 × 2360 hli | |

| Tsis muaj. | Lub npe | Hom | Ntsuas | ||

| 1 | CNC System | FANUC | OI-PF | ||

| 2 | Servo Tsav | FANUC | AISV | ||

| 3 | Servo Tsav (X / Y / C / T axis) | FANUC | AIS (X, Y, T, C) Tshwj xeeb lub cev muaj zog rau V axis | ||

| 4 | Kev taw qhia | THK | HSR35A6SSC0 + 4200L (X: 2500) | ||

| HSR35A3SSC1+2060L-Ⅱ (Y:1250) | |||||

| HSR35A3SSC1+2310L-Ⅱ (Y: 1500) | |||||

| 5 | Ballscrew | THK | BLK4040-3.6G0 + 3016LC7 (X:2500) | ||

| BLK3232-7.2ZZ + 1735LC7T (Y: 1250) | |||||

| BLK3232-7.2ZZ+1985LC7T (Y: 1500) | |||||

| 6 | Precise Bearing | NWS / Koyo | 25 TAC62BDFC10PN7B/SAC2562BDFMGP4Z | ||

| 30TAC62BDFC10PN7B/SAC3062BDFMGP4Z | |||||

| 7 | Pneumatic qhov chaw | Peb-sib koom | SMC | Qauv: AC30A-03D | |

| Solenoid valve | SY5120-5D-01 | ||||

| Muffler | UA 10-01 | ||||

| Lub tog raj kheej | CP96SDB40-80-A93L | ||||

| 8 | Hluav taws xob System | Breaker | Schneider | / | |

| Hu rau | Schneider | / | |||