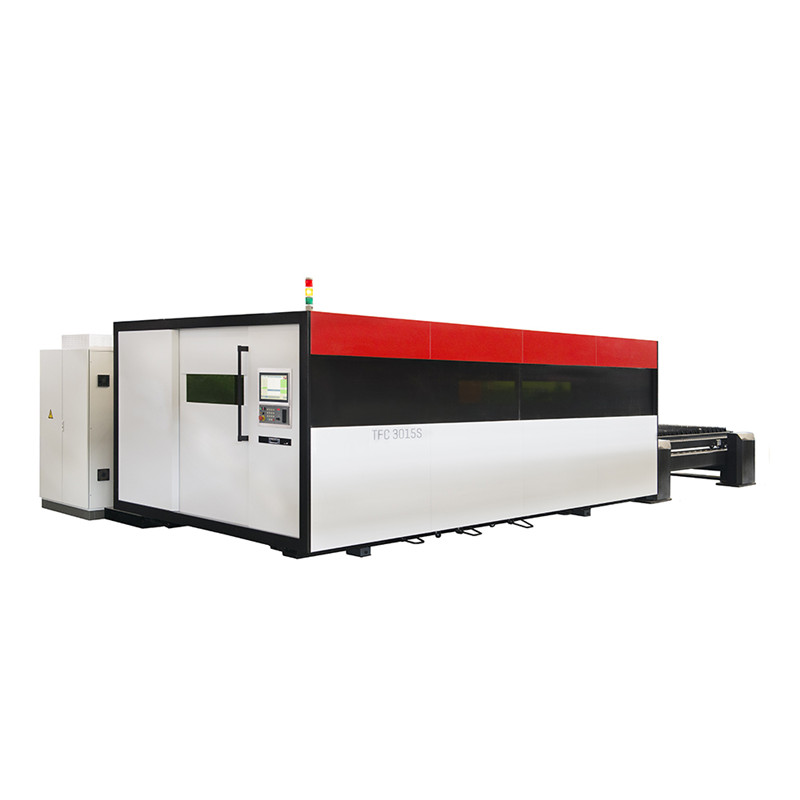

CNC Fiber Laser Tej Tshuab

EFC3015 CNC laser txiav tshuab yog tsuas yog siv rau lub tiaj phaj txiav thiab ua, los ntawm CNC system, txoj kab ncaj nraim thiab ib qho arbitrary zoo nkhaus yuav txiav thiab carved nyob rau hauv lub phaj. Nws tuaj yeem yooj yim txiav cov pa roj carbon zoo tib yam, stainless hlau phaj, phaj tooj liab, daj tooj liab thiab txhuas, thiab lwm yam hlau uas tsis tuaj yeem txiav tau yooj yim los ntawm kev ua ntau yam.

EFC3015 CNC laser txiav tshuab yog ib hom tshiab ntawm laser txiav tshuab. Cov qauv muaj siab rigidity, zoo stability, siab txiav efficiency thiab siab machining precision. Cov khoom lag luam muaj kev ywj pheej, kev nyab xeeb, kev ua haujlwm yooj yim thiab kev siv hluav taws xob tsawg. Nws belongs rau ib puag ncig tiv thaiv cov khoom, cov txheej txheem phaj loj: 3000 * 1500mm; nrog rau daim thaiv kev nyab xeeb thiab lub rooj shuttle. Tag nrho layout yog compact thiab tsim nyog.

Tsawg noj - laser tsis xav tau roj;

Kev siv hluav taws xob tsawg, txuag hluav taws xob, kev tiv thaiv ib puag ncig, kev siv hluav taws xob tsawg;

Modular qauv, cua txias system thiab lub teeb qhov system thiab laser qhov chaw yog integrated ua ke;

Kev ruaj ntseg siab - lub zog - lub sij hawm tawm tswv yim tswj qhov system nrog lub zog laser, lub zog ruaj khov 1%;

Cov nqi kho mob tsawg tsawg - fiber ntau lub taub hau siv lub iav tiv thaiv tshuab, yog tias muaj kuab paug, tsuas yog yuav tsum hloov lub lens tiv thaiv;

A. txais yuav cov ntawv qhia meej meej, ntshuam cov iav khib tsav, xyuas kom meej qhov chaw thiab rov ua haujlwm.

B. Gantry hom dual lub cev muaj zog direct tsav qauv ua rau tag nrho cov qauv ntawm cov khoom yog compact, thiab lub rigidity yog zoo, thiab qhov siab ntawm tag nrho cov tshuab yog qis.

Lub cev tseem ceeb yog welded ntawm steel daim hlau, tom qab lub ntxhib machining, cuam tshuam nrog kev co aging kev nyuaj siab. Los ntawm cov machining meej, muab lub platform thiab qib rau cov lus tsa suab.

Lub beam txais cov qauv hloov tau yooj yim, nrog kev hloov pauv thermal expansion thiab contraction muaj nuj nqi, accounting los ntawm txoj kev finite element. Beam qhov chaw yog mounted rau lub txaj los ntawm cov lus qhia meej linear dov. Kev taw qhia, iav thiab khib yog nruab nrog kev tiv thaiv npog yooj yim, kom tsis txhob muaj plua plav paug.

Cov khoom yog nruab nrog shuttle worktable, yooj yim rau thauj thiab unload khoom thaum txiav. Hauv qab ntawm lub rooj ua haujlwm nruab nrog cov khoom siv plua plav thiab cov khoom sib sau ua ke, sib txuam nrog lub log tawm lub tsheb, cov khoom seem tuaj yeem nkag mus rau hauv lub tsheb pov tseg.

Fiber laser muaj cov yam ntxwv ntawm ze infrared spectroscopy, zoo meej beam zoo, optical fiber kis tau tus mob, siab electro-optical conversion efficiency thiab thiaj li nyob.

(1) Nrog lub teeb liab laser qhia ua haujlwm.

(2) High electro-optic conversion efficiency: fiber ntau laser electro-optic conversion efficiency yog li 33%.

(3) Lub fiber ntau laser twj tso kua mis yog tsim los ntawm lub zog siab ib qho tseem ceeb semiconductor module, thiab lub sijhawm nruab nrab tsis ua haujlwm tsawg dua.

(4) Kev ua haujlwm siab, cov cua sov sab hauv yog tsawg heev piv nrog cov tsoos laser, qhov kev thov ntawm hluav taws xob thiab cua txias yog txo qis heev.

(5) Lub tshuab hluav taws xob laser tsis xav tau cov roj ua haujlwm, muaj ntawm lub lens sab hauv thiab tsis tas yuav tswj, tsis xav tau lub sijhawm pib

(1) CNC tswj qhov system siv Windows 7system, kev ua haujlwm ruaj khov thiab txhim khu kev qha.

(2) Lub zog loj AC digital servo lub cev muaj zog los xyuas kom meej tias cov khoom siv qhov tseeb thiab kev ua haujlwm zoo.

(3) Graphics simulation.

(4) lub zog tswj kev ua haujlwm.

(5) Leapfrog muaj nuj nqi.

(6) Txiav scanning muaj nuj nqi.

(7) Kev ua haujlwm ntse.

(8) Pause muaj nuj nqi, cia li sau cov txheej txheem seem.

(9) Kev saib ua ntej ntawm NC qhov kev pab cuam tuaj yeem hloov kho lub sijhawm tiag tiag los hloov cov txheej txheem kho.

(10) Kho kom raug, hloov kho cov lus qhia hauv cov txheej txheem tshawb nrhiav rau ..

(11) nws tus kheej-diagnostic muaj nuj nqi, lub tswb tshwj xeeb yog tso tawm nyob rau hauv lub operating interface.

(12) Qhov loj ntawm lub workpiece tuaj yeem nthuav dav thiab txo qis.

(13) Cov duab ua haujlwm ntawm lub workpiece.

(14) Tsis siv neeg ntug tshawb nrhiav muaj nuj nqi.

(15) Tom qab fais fab tuag, cov kev tswj xyuas tam sim no tuaj yeem kaw thiab rov pib dua tom qab lub hwj chim qhib.

Lub laser beam yog ua los ntawm fiber ntau optical, thiab lub laser beam yog parallel rau lub tsom teeb. Kev tiv thaiv lens mounted nyob rau hauv "rub hom" daim iav rooj zaum, txij nkawm thiab hloov lub sij hawm luv luv heev. Xaiv lub laser txiav lub taub hau nrog tsis sib cuag capacitive sensor, kev ua tau zoo yog ruaj khov thiab txhim khu kev qha, yooj yim siv.

Cov nta yog raws li nram no:

(1) Kev siv cov tub rau khoom hom tiv thaiv lo ntsiab muag los pab txhawb kev hloov pauv sai ntawm cov khoom siv kho qhov muag rau kev tiv thaiv lub lens collimator thiab tsom iav.

(2) Lub taub hau txiav yog nruab nrog Z axis qhov siab tsis siv neeg taug qab cov cuab yeej uas yog tswj los ntawm cov tsis sib cuag capacitive sensor. Nyob rau hauv tus txheej txheem ntawm kev txiav, tus txheeb ze txoj hauj lwm ntawm lub laser tsom xam thiab lub phaj tuaj yeem hloov kho tau los ntawm qhov kev ncua deb ntawm qhov chaw ntawm lub workpiece thiab lub nozzle.

(3) Lub laser txiav lub taub hau tuaj yeem muab CNC system nrog lub teeb liab ntawm lub cable qhib thiab txiav lub taub hau kev sib tsoo, thiab lwm yam.

(4) Cov roj siab ntawm 2.5 MPa tuaj yeem raug txiav ntawm cov khoom siv xws li stainless hlau.

(5) Cov dej txias, txiav cov pa roj, sensors, thiab lwm yam yog tag nrho cov kev sib xyaw ua ke hauv lub taub hau txiav, txo qhov kev puas tsuaj rau cov khoom saum toj no hauv cov txheej txheem txiav, txhim kho cov khoom ruaj khov.

4. Kev ruaj ntseg ntaus ntawv:

Qhov chaw ua haujlwm raug kaw nrog lub npog tiv thaiv thiab muab lub qhov rais tiv thaiv kev nyab xeeb los tiv thaiv tus neeg teb xov tooj los ntawm hluav taws xob laser.

5.Dust collection:

Qhov chaw txiav yog nruab nrog ib qho kev faib cov plua plav suction yeeb nkab, thiab lub zog centrifugal plua plav collector yog siv los tshem cov plua plav thiab plua plav. Muab lub tshuab cua tshuab thiab qhov sib txuas loj thiab 3 meter hose, lub raj txuas ntxiv yog tsim los ntawm cov neeg siv raws li qhov chaw, cov yeeb nkab cua ntev yog tsawg dua 10 meters, lub tshuab cua tshuab yog sab nraud;

6.Anti-interference muaj peev xwm:

Nrog cov kev tswj hwm digital qib siab, muaj peev xwm tiv thaiv kev cuam tshuam. Cov tshuab hluav taws xob tau txais kev tsim los tiv thaiv jamming nruj me ntsis, hluav taws xob tswj txee muab faib rau hauv thaj chaw muaj zog thiab tsis muaj zog, uas tuaj yeem tiv thaiv kev cuam tshuam ntawm cov khoom siv hluav taws xob, yog li nws tuaj yeem ua kom ntseeg tau thiab ruaj khov ntawm cov khoom lag luam.

7. Teeb pom kev zoo:

Qhov chaw txiav yog nruab nrog ob lub teeb hluav taws xob kev nyab xeeb, uas tuaj yeem muab lub teeb pom kev zoo thaum lub teeb tsis txaus lossis khaws cia, ua rau kev ua haujlwm yooj yim dua.

8. Cov khoom siv hluav taws xob:

Cov khoom siv hluav taws xob siv Schneider thiab lwm yam khoom lag luam zoo thoob ntiaj teb Lub Tuam Txhab, txhim kho kev ntseeg tau zoo ntawm kev ua haujlwm. Lub txee hluav taws xob txais kev ywj pheej kaw cov qauv, thiab cov xim ntawm cov xaim yog siv los paub qhov txawv ntawm AC, DC, lub zog thiab kev tiv thaiv hauv av.

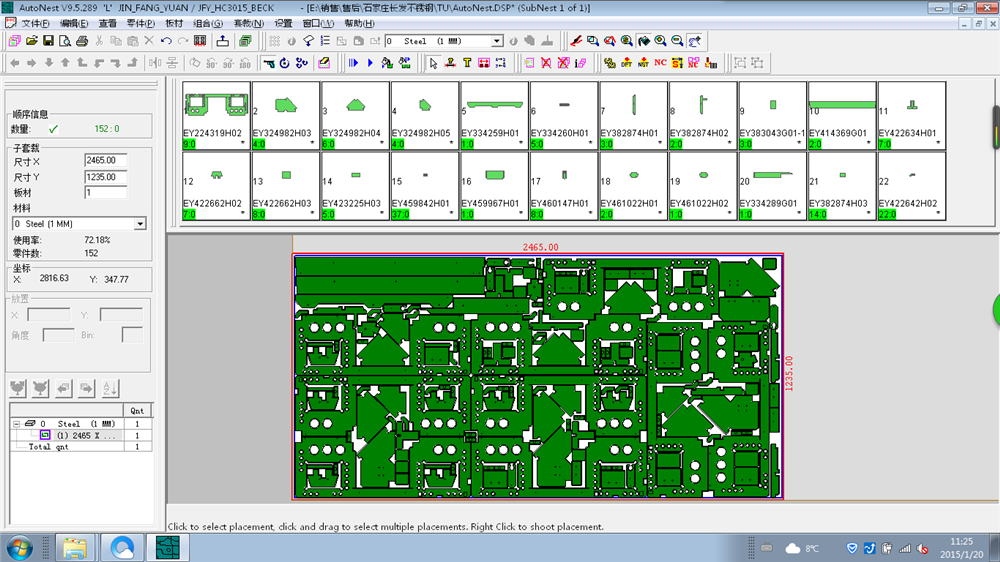

Cov khoom nruab nrog CNCKAD tsis siv neeg programming software, tsis tsuas yog tuaj yeem txuas nrog lub Hoobkas CAD / CAM thev naus laus zis, tab sis kuj txo qis kev ua haujlwm ntawm kev ua haujlwm thiab qhov ua tau yuam kev, qhov kev pab cuam zoo tuaj yeem simulate txiav. Nruab nrog txiav layout module, tsis siv neeg optimize thiab layout ntawm qhov chaw yuav tsum machined. Ob qho tib si yooj yim thiab nyuaj workpiece graphics tuaj yeem hloov mus rau hauv kev ua haujlwm.

NC laser txiav system programming software muaj nuj nqi:

(1) Tag nrho Suav ua haujlwm interface.

(2) Kev them nyiaj yug rau DWG, DXF cov tswv yim thiab tso zis tawm tswv yim.

(3) Kev kuaj xyuas tus kheej yog qhov zoo, tsis kam ua haujlwm ntawm qhov yuam kev

(4) Tsis siv neeg nesting muaj nuj nqi, txuag khoom.

(5) Tsis siv neeg ntau txheej txiav ua haujlwm.

(6) Engraving muaj nuj nqi.

(7) Ntau hom font rau UK thiab Suav.

(8) Qhov ntev ntawm cov qauv txiav tuaj yeem suav tau.

(9) Kev ua haujlwm ntawm ntug txiav.

(10) Kev tswj hwm tus nqi.

(11) Txiav database ..

(12) Cov ntaub ntawv sib pauv tuaj yeem ua tau los ntawm USB lossis RS232 interface.

* Software kev khiav hauj lwm ib puag ncig (xav kom tus neeg siv los txhawb kho vajtse)

(1) Nco 256M

(2) Hard drive 80G

(3) XP Windows operating system

(4) TFT 17 "LCD zaub

(5) 16X DVD CD-ROM

| Yam khoom | Qty. | Lus Cim / Tus Muab Khoom |

| CNC System | 1set ib | Beck Hoff |

| Tsav | 1set ib | LUST Tsav (X / Y axis) + PHASE lub cev muaj zog (X / Y axis) + Delta tsav thiab lub cev muaj zog (Z axis) |

| Laser Generator | 1set ib | RUFIBER CUT |

| X/Y axis precision iav | 1set ib | GUDEL/ATLANTA/GAMBINI |

| Z axis precision pob ntsia hlau | 1set ib | THK |

| X / Y / Z axis meej pob linear qhia | 1set ib | THK |

| Lub cev muaj zog rau shuttle rooj | 1set ib | SEW |

| Pneumatic Cheebtsam | 1set ib | SMC, GENTEC |

| Txiav taub hau | 1set ib | PRECITEC |

| Auto-program Software | 1set ib | CNCKAD |

| Cov khoom siv hluav taws xob | 1set ib | Schneider |

| Towline | 1set ib | IGUS |

| Dej Txias | 1set ib | TONGFEI |

| Tsis muaj. | Yam khoom | Specification | Chav tsev |

| 1 | Hwj chim | 380/50 ib | V/Hz |

| 2 | Yuav tsum muaj kev faib hluav taws xob | 40 | kVA ua |

| 3 | Lub zog ruaj khov | ± 10% | |

| 4 | Khoos phis tawj | RAM 256M / hard disk 80G, DVD | |

| 5 | Oxygen rau txiav carbon steel | Purity yuav tsum siab tshaj 99.9% | |

| 6 | Nitrogen rau txiav stainless hlau | Purity yuav tsum siab tshaj 99.9% | |

| 7 | Dej rau cov dej txias (dej distilled) | 100 | L |

| Conductivity:> 25μS / cm3 | μs | ||

| 8 | Dej ntshiab | 150 | L |

| 9 | Grounding kuj | ≤ 4 | Ω |

| 10 | Installation ib puag ncig kub ntawm laser generator | 5-40 | ℃ |

| 11 | Installation ib puag ncig humidity ntawm laser generator | Tsawg dua 70% | |

| 12 | Yuav tsum tau rau thaj chaw installation (cov ntsiab lus tuaj yeem xa mus rau lub hauv paus kos duab) | Lub hauv paus pob zeb thickness yuav tsum yog tuab tshaj 250 hli, lub flatness yuav tsum tsawg tshaj li 10 hli txhua 3m. Yuav tsum tsis muaj kev vibration hauv cheeb tsam installation. | |

| Yam khoom | Qty. | Chav tsev |

| Kev tiv thaiv lens | 5 | Pc. |

| Ceramic nplhaib | 1 | Tsis muaj. |

| Txiav nozzle | 6 | Tsis muaj. |

| Spanner | 1 | Tsis muaj. |

Muab tag nrho cov ntaub ntawv tsim nyog thiab cov ncauj lus kom ntxaws rau kev teeb tsa, kev ua haujlwm thiab kev saib xyuas

(1) Cov lus qhia rau Laser Tej Tshuab

(2) CNC System Data

(3) Daim duab qhia hluav taws xob

(4) Cov lus qhia rau cov dej txias

(5) Installation layout

(6) Kev kos duab Foundation

(7) Daim ntawv pov thawj tsim nyog

(8) Installation, commissioning thiab txais

Tom qab cov khoom tuaj txog ntawm tus neeg siv qhov chaw teeb tsa, peb lub tuam txhab yuav npaj cov neeg ua haujlwm paub txog rau tus neeg siv lub xaib rau kev teeb tsa, commissioning thiab qauv txiav thiab ua. Qhov kawg kev lees txais yog nqa tawm ntawm tus neeg siv qhov chaw raws li tus qauv lees txais ntawm peb lub tuam txhab. Cov khoom lees paub muaj xws li: zoo li qhov zoo, kev teeb tsa ntawm txhua qhov, txiav qhov tseeb thiab qhov zoo, kev ua haujlwm tsis zoo, ruaj khov, ua haujlwm kuaj, thiab lwm yam.

Peb lub tuam txhab yog lub luag haujlwm rau kev teeb tsa thiab commissioning .Cov neeg siv yuav tsum tau npaj cov neeg ua haujlwm yuav tsum tau ua thiab nqa cov khoom. Cov neeg siv npaj cov khoom siv thiab cov khoom siv coj mus kuaj rau kev ua haujlwm.

Thawj kauj ruam

(1) Kev lees txais ua ntej ntawm cov khoom yog ua nyob rau hauv peb lub tuam txhab.

(2) Kev lees txais cov khoom yuav tsum tau ua raws li kev pom zoo kos npe los ntawm ob tog.

(3) Kev tshuaj xyuas cov khoom zoo: cov txheej txheem kav dej yuav tsum tsim nyog, zoo huv si thiab zoo nkauj, txhim khu kev qha kev sib txuas; pleev xim rau saum npoo zoo nkauj thiab kho kom zoo nkauj; cov khoom zoo li tsis muaj khob thiab lwm yam tsis xws luag.

(4) Kev tshuaj xyuas cov khoom.

(5) Kev tshuaj xyuas ntawm qhov chaw txiav cov qauv zoo.

Kauj Ruam 2 Txais

(1) Qhov kawg kev lees txais ntawm cov khoom yog nqa tawm ntawm tus neeg siv lub xaib.

(2) Kev lees txais cov khoom lag luam yuav tsum tau ua raws li daim ntawv cog lus kev kos npe thiab kev lees txais kev txiav txim, thiab cov khoom siv rau kev sim yuav tsum muab los ntawm tus neeg siv. Yog tias tus neeg siv yuav tsum lees txais cov duab kos duab kos duab, thov muab cov duab kos duab (electronic version) ua ntej.

(3) Tom qab ua tiav kev teeb tsa thiab commissioning, yog tias cov khoom ua haujlwm ib txwm, nws yuav dhau qhov kev lees paub. Qhov kev lees txais zaum kawg yuav suav tias yog tsim nyog thiab lub sijhawm lav zoo yuav pib.

(1) Yuav kom cov tub ntxhais kawm muaj lub tsev kawm ntawv theem nrab lossis kev kawm qib siab (kev tshwj xeeb hluav taws xob yog qhov zoo tshaj plaws), tib lub sijhawm, paub txog qee yam kev paub hauv computer, thiab txawj siv computer.

(2) Tom qab lub installation thiab commissioning, peb lub tuam txhab yog lub luag hauj lwm rau muab free on-site kev cob qhia rau cov neeg siv 7 hnub, cob qhia 1 hluav taws xob tu neeg ua hauj lwm, 2 tus tswv thiab 1 mechanical tu neeg ua hauj lwm. Thiab xyuas kom meej tias cov neeg siv khoom tuaj yeem paub cov khoom ua tau zoo, ua haujlwm kom raug thiab kev txawj tu.

(3) Kev cob qhia cov ntsiab lus: cov khoom tsim thiab kev ua haujlwm, kev ua haujlwm laser, kev ua haujlwm, NC programming, laser ua tshuab, kev tu txhua hnub thiab lwm yam.

(4) Kev txhawb nqa tshwj xeeb: Cov neeg siv tuaj yeem npaj 2-3 tus neeg ua haujlwm thiab cov neeg saib xyuas tuaj rau peb lub tuam txhab txhua lub sijhawm.

Kev cob qhia raug zam los ntawm cov nqi kawm.

Cov nuj nqis uas tshwm sim thaum lub sijhawm lav yuav tsum tau them los ntawm peb lub tuam txhab, tshwj tsis yog cov uas tshwm sim vim kev siv tsis raug thiab kev ua haujlwm los ntawm cov neeg siv.

Peb lub tuam txhab muab kev pabcuam tu thiab khoom seem rau lub neej.

Cov khoom lag luam zoo lav lub sijhawm yog ib xyoos thiab lub sijhawm kho qhov muag pom zoo yog 90 hnub. Txiav nozzle, txiav cov hniav nyiaj hniav kub, lim caij, ceramic lub cev thiab optical lens yog qhov yooj yim-tawg.

Faj seeb: EFC muaj cua txiav ua haujlwm (10 kg cua compressor), tab sis cov neeg siv khoom yuav tsum tau nruab cov khoom hauv qab no los ntawm nws tus kheej.

CNC Fiber Laser Tej Tshuab ; cnc fiber ntau laser txiav tshuab ; cnc fiber ntau laser ; cnc fiber ntau laser cutter ; cnc turret punch xovxwm manufacturers

| Yam khoom | Lub npe | Hom | Qauv | OTY |

| 1 | Roj-dawb cua compressor | WW-0.9/1.0 | 1 | |

| 2 | Lub tshuab ziab khaub ncaws | PARKER | SPL012 | 1 |

| 3 | Dej Separator | domnick ua | WS 020 CBFX | 1 |

| 4 | Lim | domnick ua | AO 015 CWB | 1 |

| 5 | Lim | domnick ua | AA015 CBFX | 1 |

| 6 | Lim | domnick ua | ACS015CBMX | 1 |

| 7 | Kev sib txuas | PARKER | FXKE2 | 2 |

| 8 | Kev sib txuas | PARKER | NJ015LG | 1 |

| 9 | Siab nyem valve | FESTO | LR-1/2-D-MIDI | 1 |

| 10 | Sib koom | SMC | KQ2H12-04AS | 1 |

| 11 | Sib koom | SMC | KQ2L12-04AS | 6 |

| 12 | Sib koom | SMC | KQ2P-12 | 1 |

| 13 | Gas kav | SMC | T1209B | 15m ua |

| 14 | Sib koom | EMB | VADKO 15-RL/WD | 1 |

| 15 | Sib koom | EMB | X A15-RL/WD | 1 |

1. Main Specification

| Yam khoom | Specification | Chav tsev | |

| 1 | Daim Ntawv Txiav Loj | 3000 × 1500 hli | mm |

| 2 | Stroke ntawm X axis | 3000 | mm |

| 3 | Stroke ntawm Y Axis | 1500 | mm |

| 4 | Stroke ntawm Z axis | 280 | mm |

| 5 | Max. Pub ceev | 140 | m/min |

| 6 | Txiav raug | ± 0.1 | hli/m |

| 7 | Rated Laser zog | 1000 | W |

| 8 | Txiav Thickness (thaum qhov kev txiav txim yuav tsum tau ntsib) | Carbon hlau 0.5-12 | mm |

| Stainless hlau 0.5-5 | mm | ||

| 9 | Ruaj khov txiav Thickness | Carbon hlau 10 | mm |

| Stainless hlau 4 | mm | ||

| 10 | Lub zog nkag | 31 | kVA ua |

| 11 | Shuttle rooj sib pauv sijhawm | 10 | S |

| 12 | Tshuab hnyav | 8 | t |

2.SPI Laser Resonator

| Qauv | TruFiber -1000 |

| Lub zog nkag | 3000 W |

| Tso zis zog | 1000 W |

| Laser zog stability | <1% |

| Laser wave length | 1075nm ua |

3. CNC System

| Yam khoom | Specification |

| CNC system | Beckhoff |

| Processor | Dual-core 1.9 GHz |

| System nco muaj peev xwm | 4 GB ua |

| Hardware nco muaj peev xwm | 8gb ua |

| Zaub screen hom & loj | 19 "xim kua siv lead ua kua |

| Txheem kev sib txuas lus chaw nres nkoj | USB 2.0, Ethernet |